First Attempt

My first attempt at working with plaster to make a pendulum. This process involved turning plaster on a lathe to get the pendulum form. Making 2 part plaster molds. Making a wax cast and cleaning it up. Attaching the wax casts to a wax tree and again creating a plaster cast. Melting out the wax and finally pouring aluminum to create the final metal form to be finished.

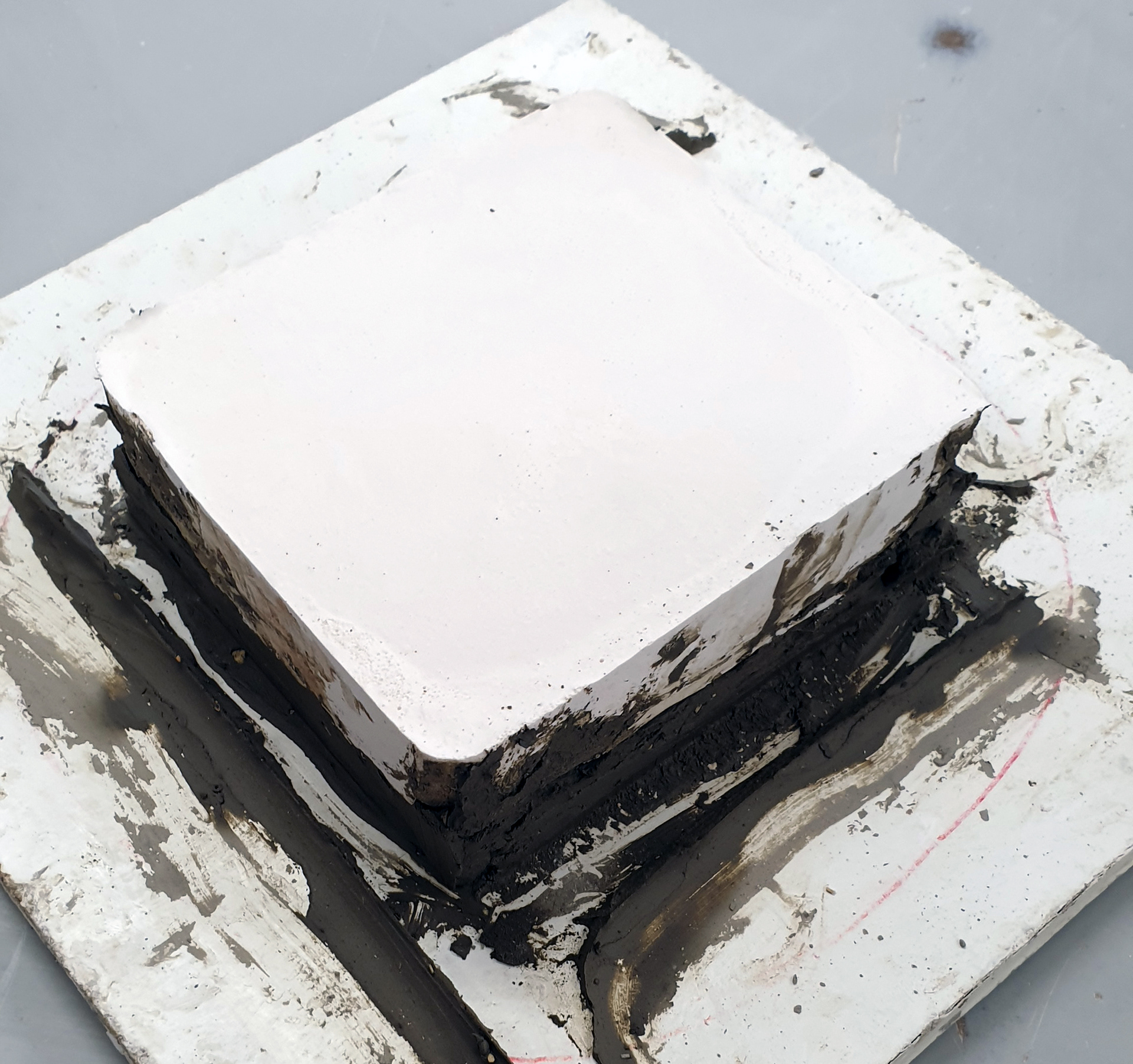

The turned plaster, done on a plaster lathe.

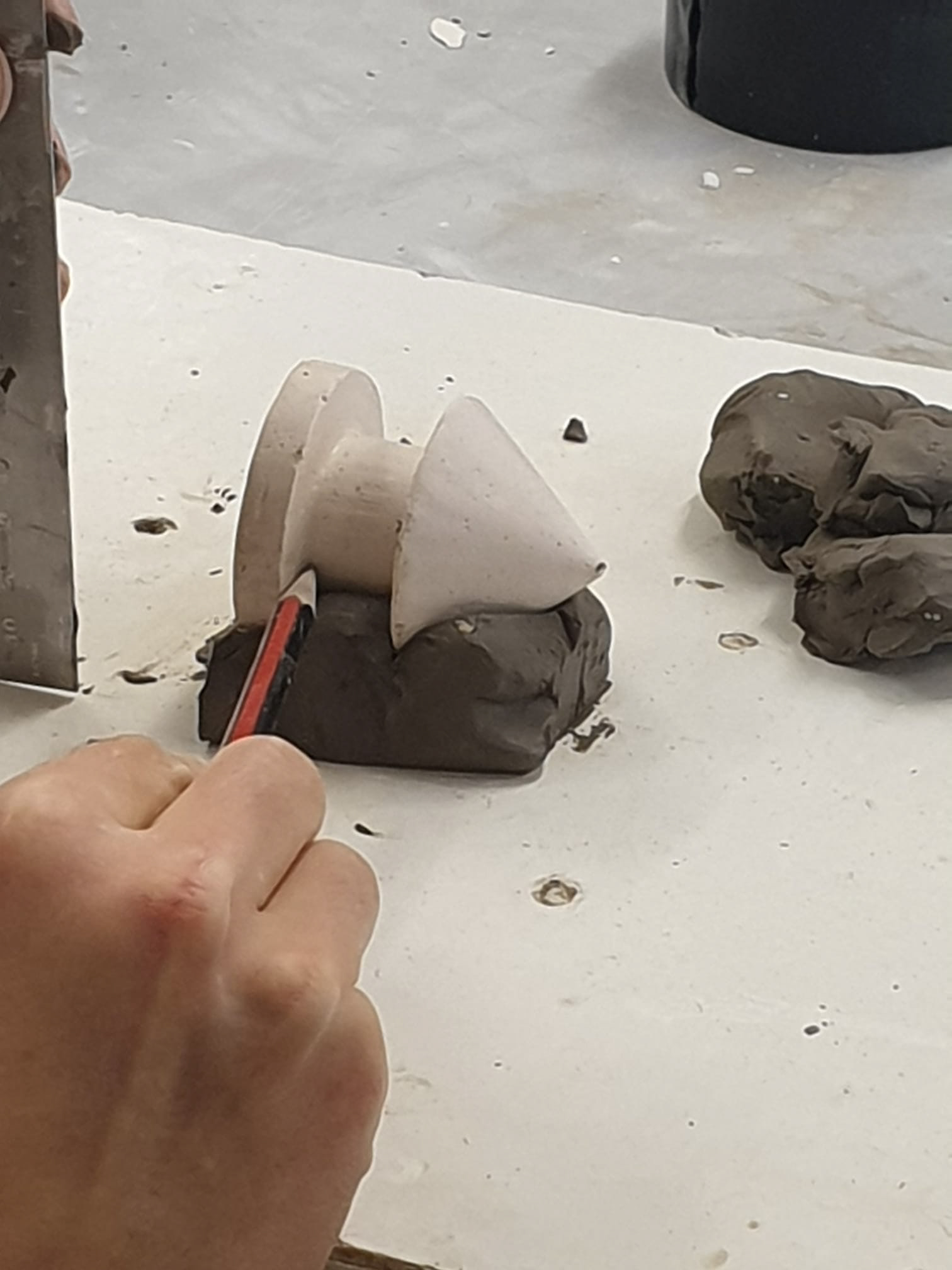

Making a 2 part mold from the turned plaster piece.

Making a 2 part mold from the turned plaster piece.

Making a 2 part mold from the turned plaster piece.

The mold when separated. This was then cleaned up to deal with the problematic overhang.

The wax cast, made from the 2 part mold.

The wax cast, made from the 2 part mold.

Assembling the wax tree for casting, including runners, risers and the sprue.

Assembling the wax tree for casting, including runners, risers and the sprue.

Assembling the plaster mold, building in layers with increased material coarseness and a final layer of chicken wire for structure.

Assembling the plaster mold, building in layers with increased material coarseness and a final layer of chicken wire for structure.

Assembling the plaster mold, building in layers with increased material coarseness and a final layer of chicken wire for structure.

Breaking apart the plaster mold to reveal the casted aluminum tree.

The final aluminum tree casts to be cleaned up.

Video of aluminium casting.

Second Attempt

My second attempt followed a very similar process to the first. This time using a 3D print as the base form to create a cast from. This final form was then casted in bronze.

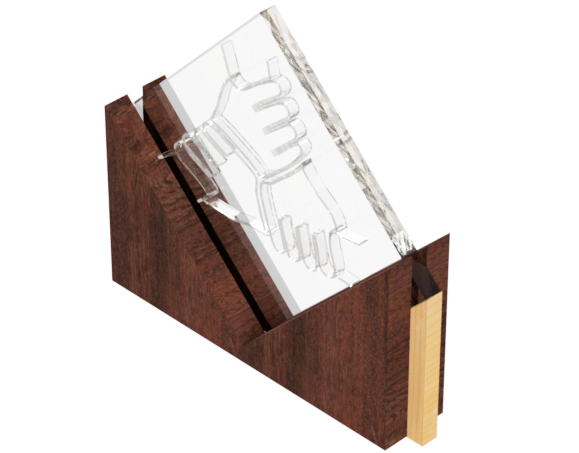

The 3D printed hand to mold.

The 3D printed hand to mold.

Creating a 2 part plaster mold from the 3D print.

Creating a 2 part plaster mold from the 3D print.

Creating a 2 part plaster mold from the 3D print.

Creating a 2 part plaster mold from the 3D print.

Creating a 2 part plaster mold from the 3D print.

The final mold to clean up & wax cast.

Casting the wax.

The wax cast when first taken out.

The wax cast being cleaned up & refined.

The final wax cast, cleaned up & refined.

Making the wax tree.

Adding runners.

Adding runners.

Adding runners.

Adding the plaster layers.

The final plaster mold after melting out the wax & drying.

The foundry furnace.

The molds, ready for pouring.

The molds, after pouring.

The molds, removed from the sand bed.

The resulting cast to be cleaned up.

The resulting cast being cleaned up.

The resulting cast being cleaned up.

Need a hand?

The final casted outcome.

The final casted outcome.

Video of bronze casting.